The word "centrifugation" refers to a technique for separating mixtures that involves rotating and centrifugal force. Particles can be separated by spinning based on a variety of factors, such as size, form, density, and viscosity.

A centrifuge is a laboratory tool used to separate fluids, gases, or liquids depending on their densities.

British military engineer Benjamin Robins came up with the concept for the first centrifuge when he created a gadget that resembled an arm spinning around an axis to measure drag on objects. By enhancing this design, the Prandtl siblings later created the first effective centrifuge to separate milk from cream. Separation is achieved by quickly spinning a receptacle holding material; the centrifugal force pushes heavier elements to the outside of the container.

In addition to being used in science and medical studies, centrifuges are used in everyday living. It can be used to purify nucleic acids, viruses, proteins, and intracellular structures.

Table of Contents

- Principle of a Centrifuge

- Parts of a Centrifuge

- Types of centrifugation techniques

- Types of Centrifuges

- Benchtop or Tabletop centrifuges

- Gas centrifuges

- Haematocrit centrifuge

- Microcentrifuge

- Refrigerated Centrifuges

- High-Speed Centrifuges

- Low-speed centrifuges

- Continuous flow centrifuges

- Ultracentrifuges

- Centrifuge Operating Procedure

- Applications of Centrifuge

- Advantages of Centrifuge

- Limitations of Centrifuge

- Precautions

- Centrifuge Examples

Principle of a Centrifuge

Because of gravity, the centrifuge uses the settling concept. The centrifugation method divides particulates floating in a liquid medium using a rotating field. These are placed in flasks or containers and inserted into the rotor of the centrifuge. Gravity causes suspended particulates to separate from liquid during sedimentation. The material that is suspended may contain powder or bits that resemble clay.

Simple filtering separates particulates smaller than 5 micrometers, which begin Brownian motion and do not sediment under gravity, from those that are bigger. The central pull can be used to sort these particles.

Parts of a Centrifuge

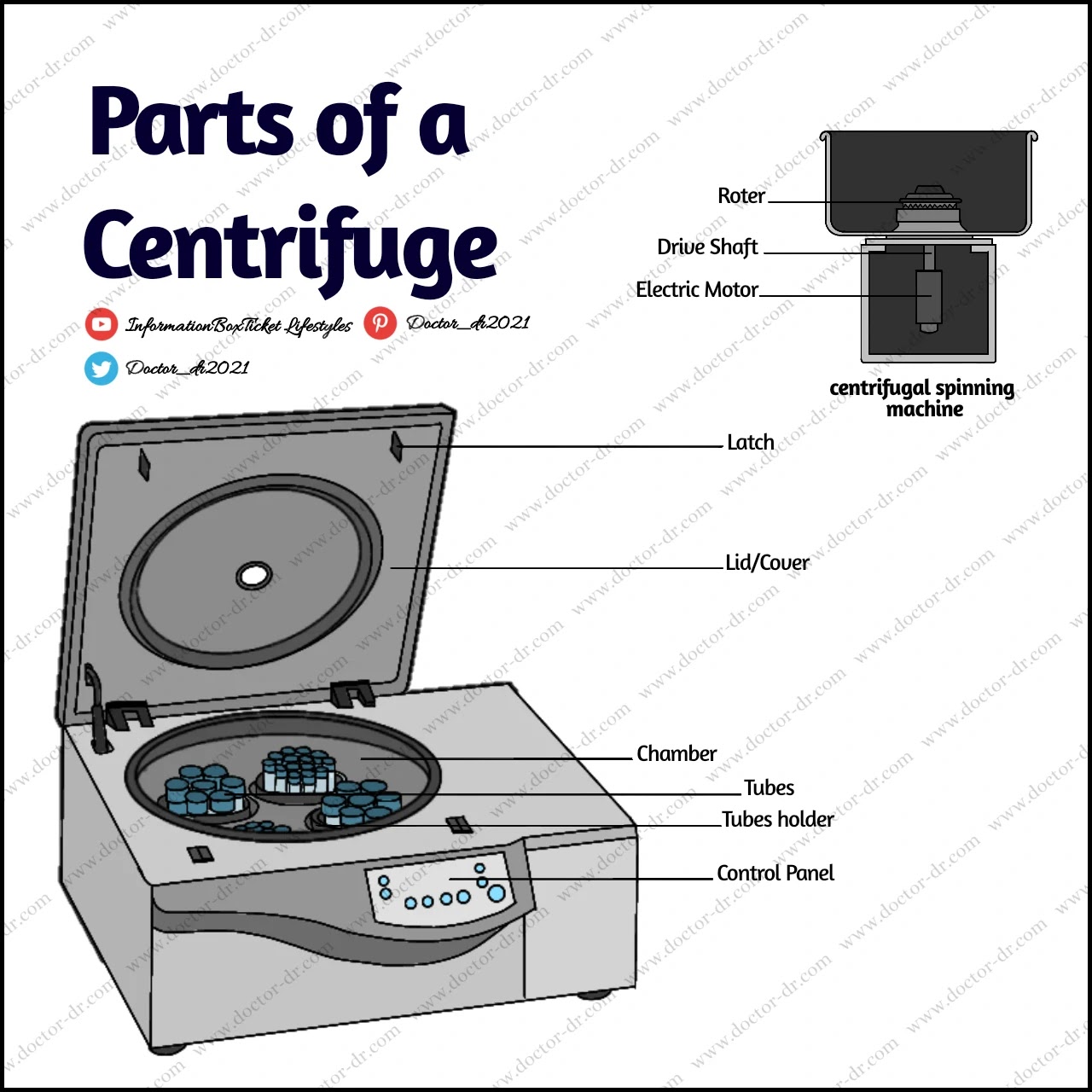

The following is a description of a few of the centrifuge's typical components:

1. Motor: The centrifuge's strong core component that generates the spin is the motor.

2. Rotor assembly: The rotor component is made up of a motor shaft and a rotor. The rotating components are supported by the motor shaft. The rotor head is connected to the engine, which supports the receptacles that hold the tubes containing the centrifuged material. It is a device that transforms electrical energy into kinetic energy. The rotational speed of two rotors of varying sizes can be the same. The acceleration of such blades varies with their radii and rotational motion. As a result, the recognized standard measure for rotation speed is relative centrifugal force (rcf).

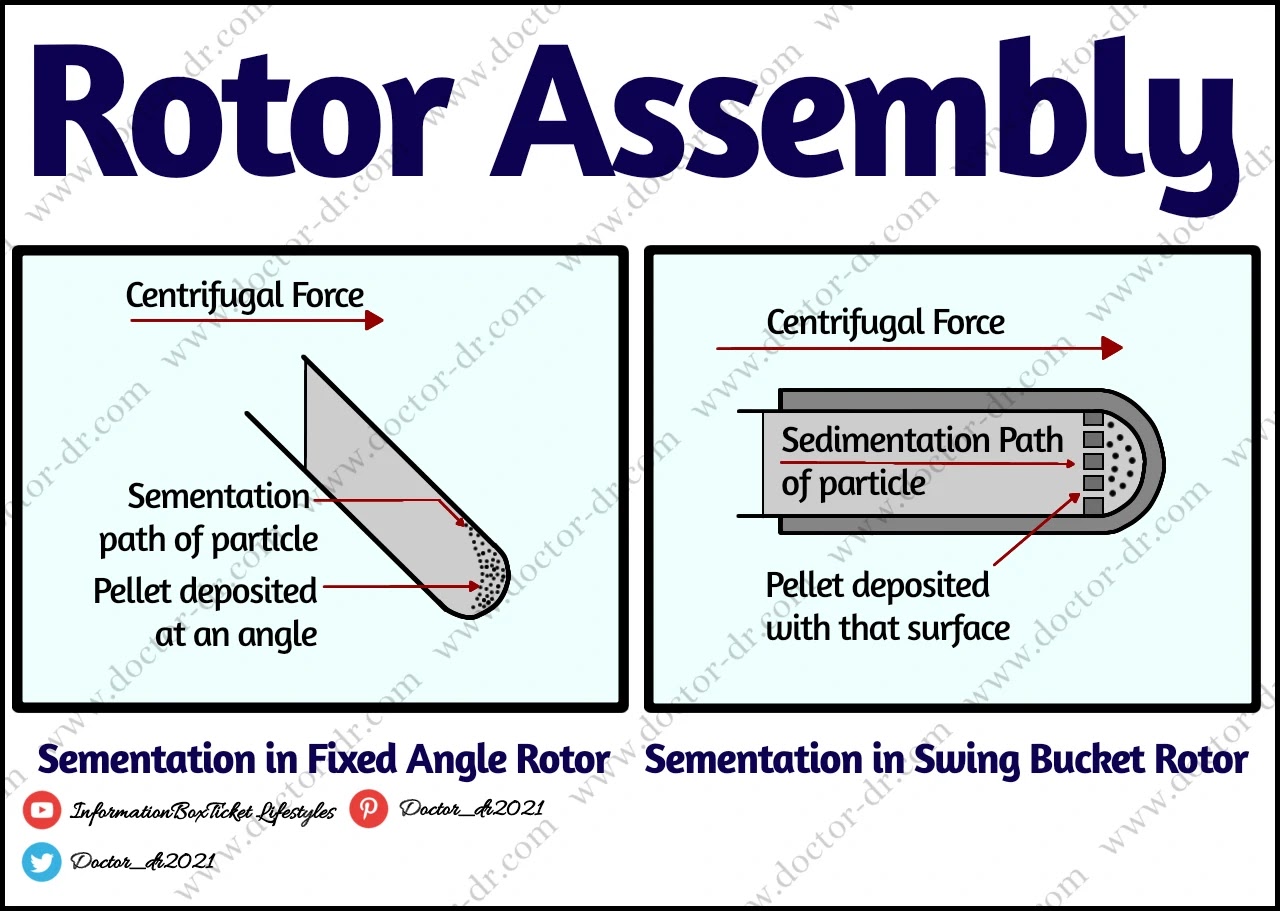

Rotors are classified into three types:

a) Fixed angle rotors: These rotors, which are used in differential centrifugation, position the tubes at an angle of 14 to 40° to the vertical, allowing particles to traverse a brief distance while traveling radially outwards. Because the sedimentation orientation is the same as the direction of rotational force, sedimentation occurs at an angle at the sides of the tubes. After striking with the wall surface, the pellets (cluster of sediments) fall at the intersection of the base and the wall surface.

b) Swinging bucket/ Horizontal rotors: During acceleration, these rotors, along with the centrifuge tubes, move out to a horizontal position, allowing particles to traverse a greater distance and allowing for simpler extraction of supernatant from pellet. These actuators are used in density gradient spinning.

c) Vertical rotors: These keep the tubes vertical, parallel to the motor axis, and the particles travel shorter lengths with shorter separation times. It is used for isopycnic and density gradient separation, but not for pelleting because centrifugal force spreads the pellets out along the full exterior wall of the tube.

3. Containers: Various containers, such as test tubes, blood bags, cuvettes, centrifuge tubes, and so on, are kept in the rotors so that the material spins along with the rotor.

4. Control Panel: It is used to regulate various factors such as temperature, rotational speed (rcf or rpm), and so on.

5. Latch: The latch holds the cover closed when a tube breaks or there are other problems with the centrifuge while it is operating.

6. Lid: To avoid accidents, the centrifuge will only spin if the lid is closed and secured.

Types of centrifugation techniques

There are two kinds of centrifugation techniques:

1. Preparatory centrifugation: Preparatory spinning is concerned with the separation and purifying of biochemically important components such as tissue, cells, subcellular structure, membrane vesicles, and other particles.

2. Analytical centrifugation: Analytical centrifugation is used to describe purified proteins.

1. Preparative Centrifugation

Preparatory centrifugation is classified into two kinds based on the mixture. They are as follows:

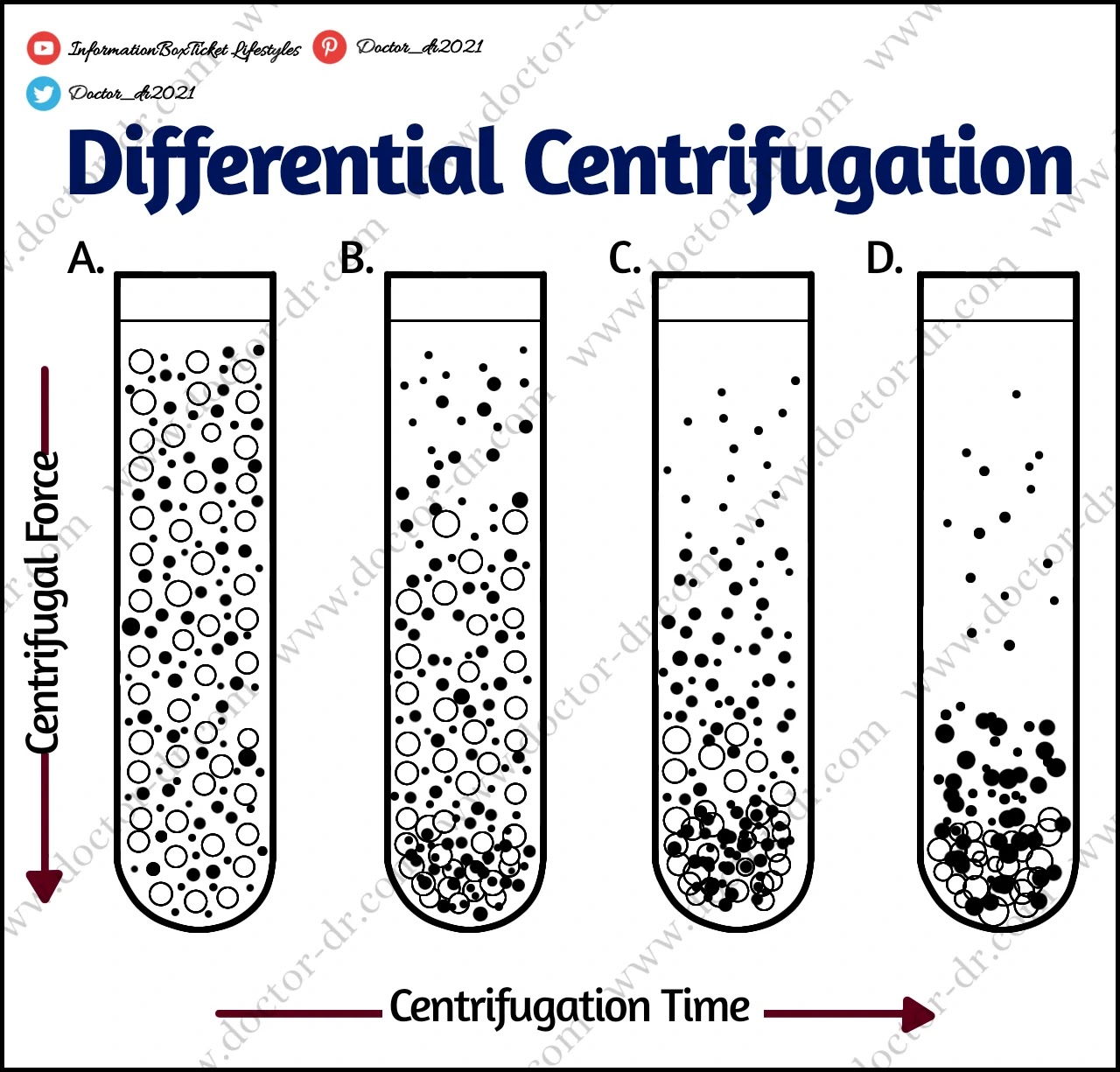

i) Differential centrifugation

It sorts elements by form, size, and density. A suspension of particles of various densities or sizes will sediment at different rates, with bigger and denser particles sedimenting faster. A series of pellets holding cells with a declining sedimentation rate will result from a series of increasing centrifugal force cycles on a cell suspension.

ii) Density gradient centrifugation

It sorts particles depending on buoyancy or sedimentation rate. A sample mixture is placed on top of a preformed liquid density gradient, such as CsCl for DNA banding and isolation of plasmids, nucleoproteins, and viruses; NaBr and NaI for lipoprotein fractionation; Percoll, Ficoll, Metrizamide, Dextran for whole cell separation; and sucrose solution for DNase, RNase, and Protease separation.

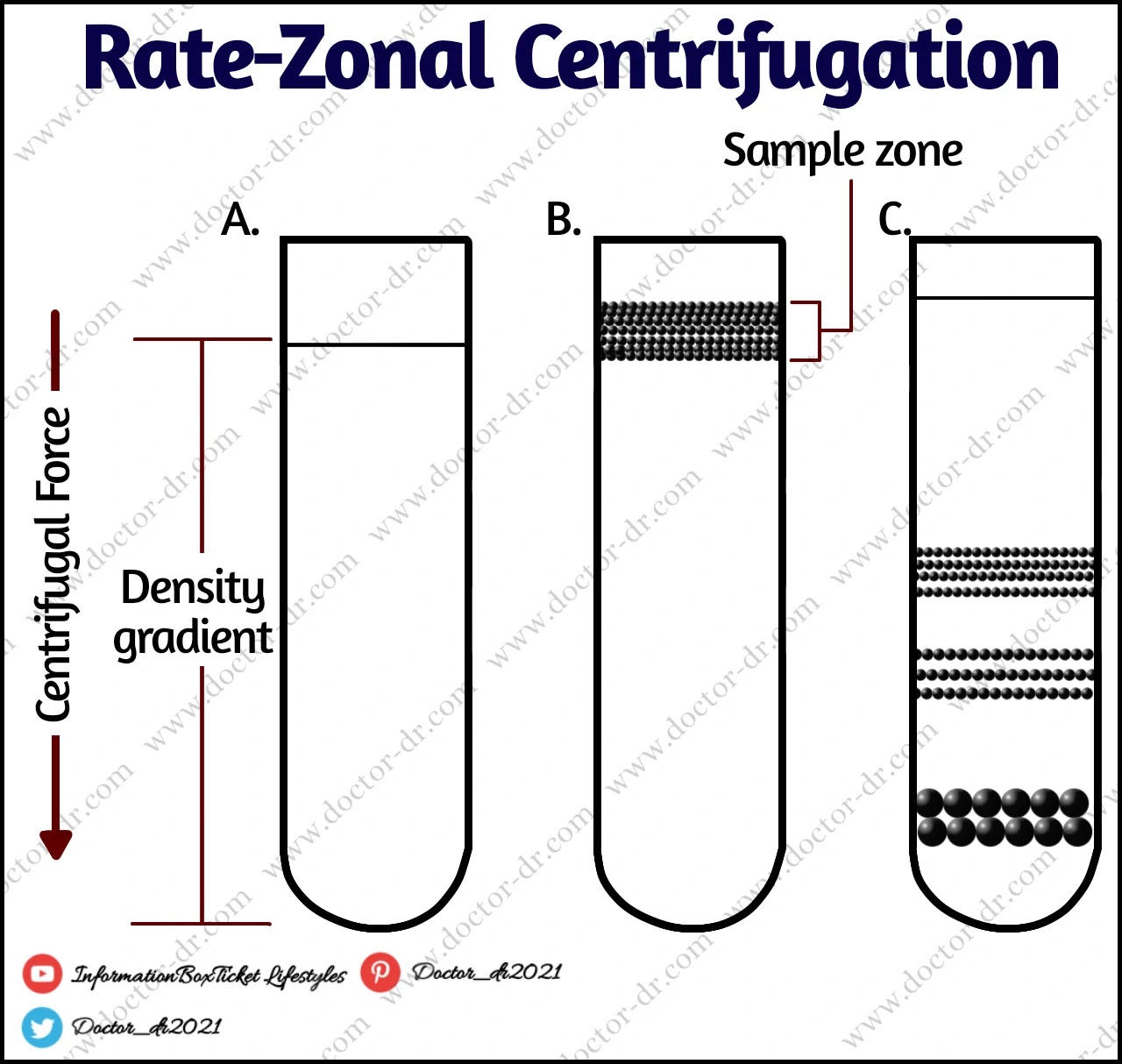

Rate-zonal and isopycnic centrifugation are the two kinds of density gradient centrifugation.

Rate-zonal centrifugation

The sample is placed as a tiny zone on top of a density gradient. Particles move at different rates due to centrifugal force, depending on their bulk. The primary factors of how fast particles settle are size and density. As the particle band drops through the density medium, zones of similar particle size form as the faster sedimenting particles past the slower ones.

Isopycnic centrifugation

In an isopycnic separation, also known as buoyant or equilibrium separation, particles are divided solely based on their mass. The gradient medium must have a greater density than the particles that must be divided.

Particles move from an evenly mixed sample and density gradient under the influence of centrifugal force until their densities match those of the surrounding medium. Particles of a certain density settle after spinning until their density matches that of the gradient media. (i.e., the equilibrium position).

2. Analytical Centrifugation

Its goal is to gather data to describe the spun sample (sedimentation velocity, viscosity, concentration, etc.), identify the relative molecular weight of the solutes, biomolecule purity, detect conformational changes in protein structure, and so on.

Types of Centrifuges

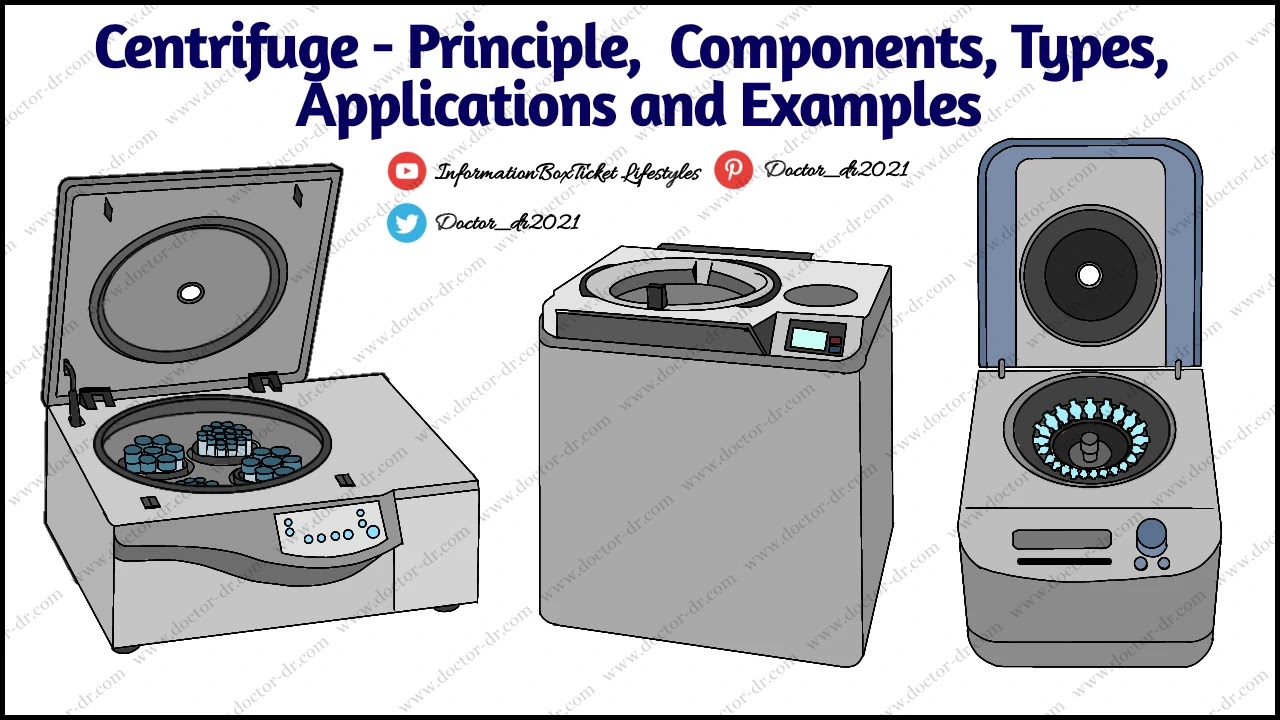

Benchtop or Tabletop centrifuges

- Because of their small size, they can be useful in small labs with restricted room.

- These are small and are commonly used in research and hospital labs.

- A tabletop centrifuge includes a lid that conceals the equipment used to operate the centrifuge as well as a rotor with racks for test tubes.

Gas centrifuges

- These are used to sort molecules according to their masses and vapors according to their isotopes.

- They are specifically used in the isolation and differentiation of uranium-235 and uranium-238.

Haematocrit centrifuge

- Haematocrit centrifuges have speeds ranging from 7000 to 15000 rpm.

- Hematocrit centrifuges are used to determine the volume-based erythrocyte proportion in blood. It is used to generate plasma for photometric measurement of newborn blood bilirubin concentrations.

Microcentrifuge

- Because of their compact size, they have a very small dimension and take up very little space on the desk.

- These are commonly used in biological uses and perform well with tiny tubes (up to 2.0 ml).

- They are used to microfilter tiny quantities of aqueous samples, as well as to contain pelleted nucleic acids, proteins from solutions, and other substances.

Refrigerated Centrifuges

- These centrifuges operate at maximum speed while maintaining a steady temperature.

- Because of its temperature range of -20 to -40 degrees Celsius, it is used to examine DNA, RNA, PCR, and antibodies.

- They are commonly used to rapidly gather sedimenting materials such as yeast cells, chloroplasts, and others.

High-Speed Centrifuges

- A high-speed centrifuge is a form of centrifuge that can spin at speeds varying from 15,000 to 30,000 revolutions per minute.

- For the critical analysis of fragile biological molecules, high-speed centrifuges contain a mechanism that regulates both the temperature and the speed of the operation.

- There are three types of rotors used in these centrifuges: set angle, rotating bucket, and vertical.

Low-speed centrifuges

- These are commonly used in labs for regular particle sorting at speeds ranging from 4000-5000 rpm.

- Temperature control is rare, and they are frequently used at ambient temperature.

- Swinging bucket and fixed-angle rotor centrifuges are used in these machines.

Continuous flow centrifuges

- It allows for the spinning of huge amounts of materials without affecting sedimentation rates.

- They also have larger capacities, which saves time by removing the need to frequently load and discharge the material, as is required with conventional centrifuges.

Ultracentrifuges

- The ultracentrifuge is a highly developed and complex centrifuge that can rapidly separate tiny molecules that ordinary centrifuges cannot.

- Rotor rates in ultracentrifuges can vary from 60,000 to 150,000 rpm.

- They are larger and process samples in groups or as continuous flow devices.

Types of Ultracentrifuges

1. Preparative Ultracentrifuges

- Preparative ultracentrifuges are centrifuges that use centrifugation to extract and sort particles within an investigation.

- The contents of the containers are inspected after the centrifugation process when a cycle is made for an ultracentrifuge, as opposed to the centrifuge for analysis, which examines during the centrifugation.

2. Analytical Ultracentrifuges

- Analytical centrifuges are ultracentrifuges that are used to analyze various particulates within a material.

- It is used to conduct a chemical analysis of proteins in solution.

- These are outfitted with sensing devices that monitor the spin and movement of the components in real time, allowing the sedimentation coefficient to be calculated.

Centrifuge Operating Procedure

1. Inspect the centrifuge to ensure it is in good working order, is not damaged, and can move freely.

2. After selecting the appropriate centrifuge tubes or receptacles, inspect them for blemishes or fractures. Any damaged or faulty tubes or receptacles should be destroyed.

3. Fill the tubes with your chosen beverage. Never fill cylinders or receptacles more than halfway.

4. Ensure that the centrifuge tubes are balanced; measure each tube individually on a scale to ensure that their weights are identical. Avoid relying entirely on loudness to balance! This is particularly true for solutions having a variety of sample kinds or concentrations.

5. Firmly screw the spinning tubes' covers on.

6. Make sure the centrifuge tubes' exteriors are dry and spotless before placing them.

7. Keep the centrifuge cylinders level.

8. Close the cover. Make sure the cover fits snugly.

9. Set the run duration and pace.

10. Do not abandon the centrifuge when it looks to be running and at maximum speed. Examine the area for any odd vibrations or sounds.

11. If you hear an unusual noise or sense intense shaking, turn off the centrifuge and extract the sample. An poorly balanced centrifuge is a common source of this. If the problem persists despite the centrifuge being correctly balanced, do not use it until it has been fixed.

12. After the centrifuge has completed its cycle, wait until the rotation stops before removing the cover. Before the centrifuge has ceased rotating, never handle or uncover the lid. Prematurely stopping the machinery may cause mechanical malfunction and harm.

13. It is best to wait at least 10 minutes after the spinning has ceased before removing the cover to enable the aerosols released during centrifugation to settle.

14. After the centrifuge has ceased whirling, samples can be removed.

Applications of Centrifuge

- Centrifuges are used in chemistry, biology, biochemical, and clinical labs, for example, to measure the sedimentation rates of different blood types.

- In the dairy industry, these are used to extract cream (fat) from milk, a procedure known as churning.

- In water purification, massive centrifuging devices spin mud and sludge out of the water to create cleaner water. Similarly, in oil platforms, solid matter is separated from newly drilled-out petroleum.

- Furthermore, large rotating wheels are used to mimic a high-gravity setting for pilot practice. As a result, these are crucial in aviation and space.

- Centrifugation is used in the production of biological products and bulk medicines, as well as in medication biopharmaceutical research.

- It is used to remove water from vegetables after rinsing it in a salad processor, as well as to separate chalk powder from water.

- It is helpful for isotope separation in nuclear weapon design.

Advantages of Centrifuge

- Enclosed action and, as a result, a clean look

- Rapid startup and termination

- Low initial cost-to-capacity ratio Easy automation and uninterrupted running

- Quickly change operating settings

- Outstanding work and adaptability

- Simple functioning and straightforward implementation

Limitations of Centrifuge

- It is extremely challenging to separate light particles (with almost no bulk).

- Regardless of its type, a centrifuge is a highly complex electrical device that requires specialized servicing in the event of a malfunction, making device upkeep extremely difficult and costly.

- It consumes a lot of energy because it has so many power-hungry functions like temperature regulation and rotor spinning.

- Centrifuges cause noise disturbances due to their rapid rotation speeds per minute. Because it employs rotations, vibrations are inevitable, causing noise pollution and prohibiting its use in some areas.

- When the main machinery fails, a backup machine is usually needed to come in.

- Polymers are widely used.

Precautions

- Check that the centrifuge is on a suitable area before beginning the process.

- While the blade is running, keep the cover closed.

- Unplug the centrifuge if it moves or rattles.

- Before using tubes, ensure that they are compatible with the applications and parameters. The cylinders used in the centrifuge should be in a matched group.

- To weight tubes evenly, balanced adjacent and opposing loads should be used. To equalize the pipelines, use mass rather than volume.

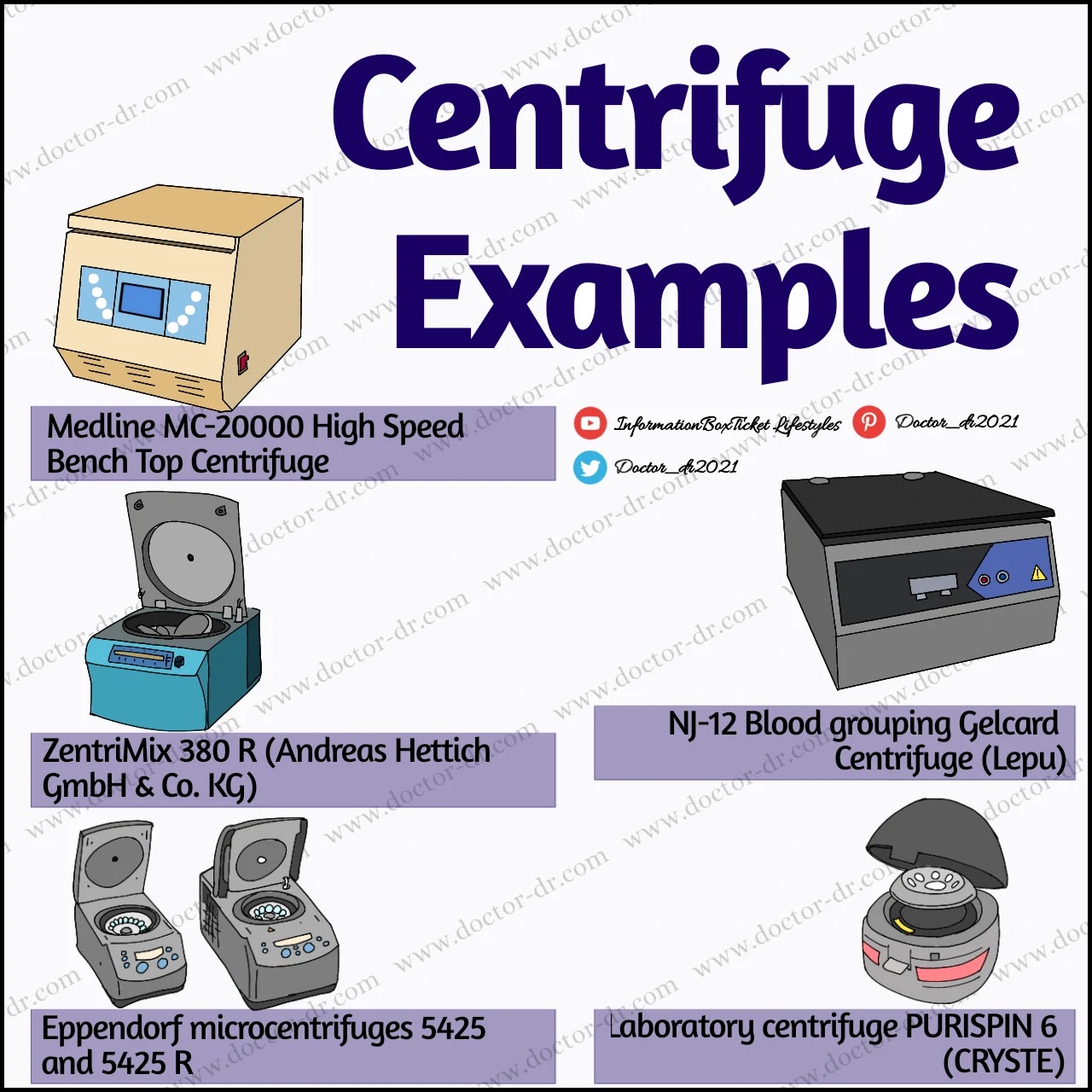

Centrifuge Examples

Laboratory centrifuge MC-20000 (Medline Scientific)

- The RCF number is displayed immediately.

- Microprocessor control, brushless motor, and widescreen digital monitor indicate speed, time, temperature, and other information.

- Electronic door locks, imbalance, over-speed, and over-temperature warnings are all built-in safety features.

Analytical centrifuge ZENTRIMIX 380 R (Andreas HETTICH GmbH & Co.KG)

- The dual centrifuge ZentriMix 380 R facilitates numerous common operations in research and analysis labs.

- Two common uses are creating nanoparticles in sealed (sterile) containers and combining heavy or difficult-to-mix components.

- When compared to standard lab shakers, the noise level during the show is negligible.

Laboratory microcentrifuge 5425 (Eppendorf SE)

- The improved cooling system of the Centrifuge 5425 R ensures optimal separation results and constant cooling at 4°C, even when the rotor is running at full speed.

- The Eppendorf Kit rotor F-45-18-11-Kit can centrifuge materials in 18 spin columns and 1.5 or 2.0 mL tubes at a maximal speed of 18,565 x g.

Laboratory centrifuge PURISPIN 6 (CRYSTE)

- Outstanding durability.

- Simple to use.

- Silent operation.

- Design that is small.

Blood bank centrifuge NJ-12 (Lepu Medical Technology)

- Maximum speed: 3000 rpm.

- Precision at high speed.

- Little noise.

- Automated oversight of the entire procedure.

%20Technique%20A%20Comprehensive%20Guide%20to%20Water%20Quality%20Testing%20and%20Microbiological%20Analysis.webp)

~1.webp)

.webp)