Inoculation is the procedure of adding bacteria to a culture media so they can grow there in microbiology. It is commonly used to introduce vaccines, serum, or other antigenic substances into the body to boost immunity against a specific illness.

Before incubation, multiplication, or growth, microbes like bacteria or yeast are added to plated or tubed growth media using hand-held, portable inoculating loops and needles.

Usually, the inoculum is introduced and spread into a liquid medium, streaked onto, jabbed into, or both solid agar-based media.

A fundamental tool used primarily by microbiologists to take and transfer a small sample (inoculum) of a microbe culture, for example, to strip on a culture plate, is an inoculation loop, also known as a smear loop, inoculation wand, or microstreaker. It is a tool that is frequently made of nichrome or platinum wire and has a tip with a tiny loop that ranges in thickness from 2 to 5 millimeters. Loops are necessary for moving liquid media between Petri dishes or liquid media. An inoculation loop is used to collect the liquid media. Larger samples can also be extracted using loop wires.

Needles move Petri plates or other solid media between them. The use of an inoculation needle is necessary when removing solid or thick substance. These are effective at removing small colonies of microscopic organisms from samples.

These are used to collect small amounts of microorganisms and transmit them before further research, microscopic inspection, or serial dilution.

Table of Contents

- Principle of Inoculating Loops and Needles

- Parts of Inoculating Loops and Needles

- Types of Inoculating Loops and Needles

- Inoculating Loops and Needles Operating Procedure

- Applications of Inoculating Loops and Needles

- Advantages of Inoculating Loops and Needles

- Limitations of Inoculating Loops and Needles

- Precautions

- Inoculating Loops and Needles Examples

Principle of Inoculating Loops and Needles

The loops and needles can be sterilized by being flamed until they are red hot in order to stop sample infection. They are then prepared to take up, transfer, and inoculate the microbial sample into the media or make a smear once they have cooled.

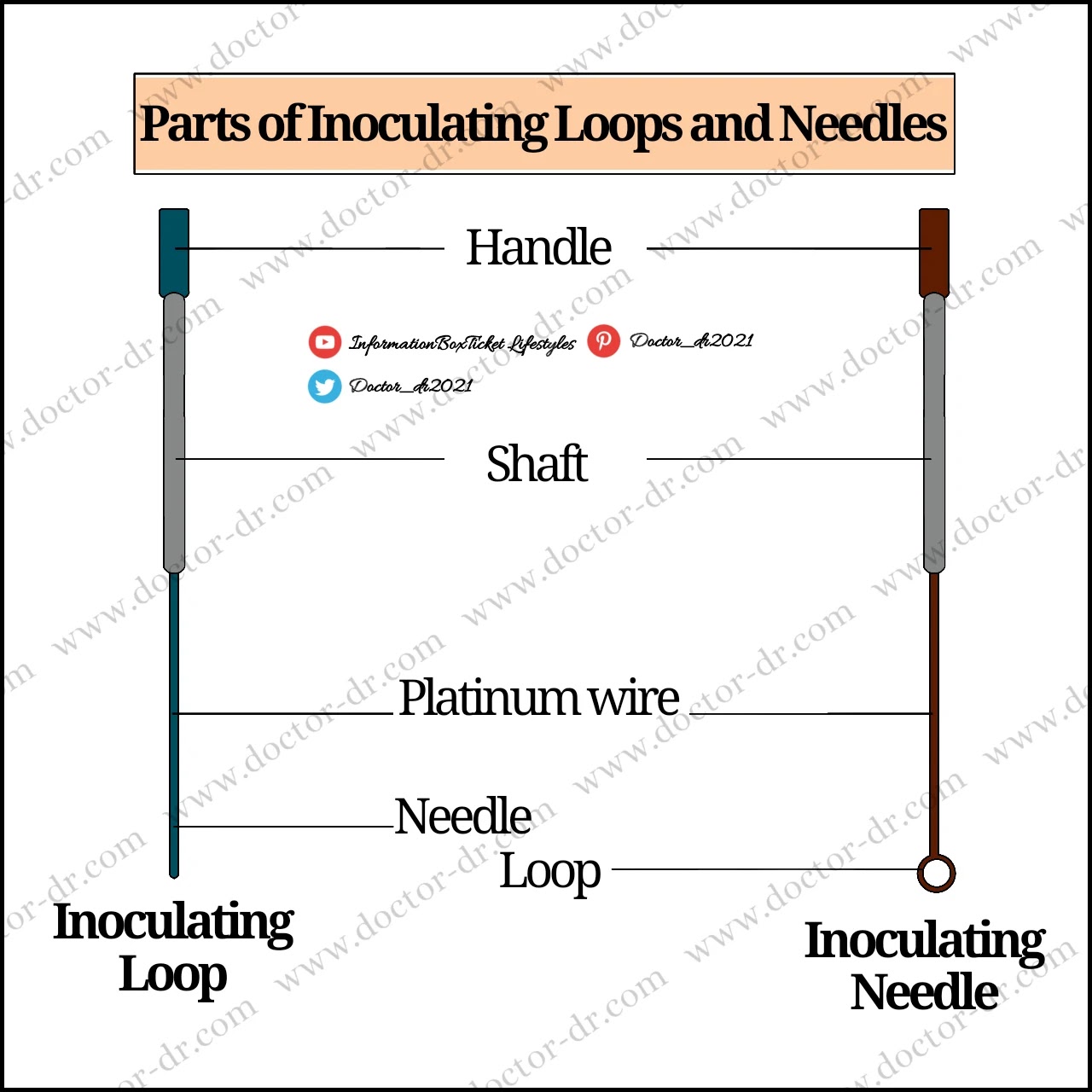

Parts of Inoculating Loops and Needles

- Handle: To apply the inoculating loop or needles without becoming fatigued, grasp the handle portion of the loop or needle. It comes in an insulated or non-insulated version and is made of aluminum and brass. It has an 8-inch grip.

- Shaft: The loop shaft is made of nickel-plated steel. PVC is used to insulate the shaft of the loop handle, providing the user with additional thermal protection.

- Turret: It can contain platinum or nickel-chromium wire.

- Loop: The extremity of the platinum or nichrome wire attached to the turret is twisted to form a loop structure. The metal is oxidation and high temperature resistant. The loop has a diameter between 2 and 5 millimeters.

- Needle: It is essentially the same as the loop but makes use of a single wire.

Types of Inoculating Loops and Needles

The two major categories of inoculation loops are as follows:

1. With calibrated inoculation loop (Calibrated)

- It is used to cultivate quantified specimens.

- Sizes of 1µL and 10µL are both offered.

- calibrating with a license.

2. Without calibrated inoculation loop (Noncalibrated)

- With an internal diameter (Ø) of 2, 3, 4, or 5 millimeters, various versions are offered.

- It is easy to use and discard.

- Loops for vaccination are prepared for use.

- It has been sterilized using gamma radiation.

Based on their longevity, vaccination syringes are divided into two categories: reused and disposable.

1. Reusable inoculation needle: The typical reuse inoculation syringe is made up of a metallic handle and nichrome or platinum filament that are joined together.

2. Disposable inoculation needle: Plastic epoxy is typically the main ingredient. The dulling of the needle's base results in the creation of a rounded point. These are employed in environments where the flame is impractical, such as under hoods and in anaerobic chambers, thereby removing the risk of infection from pathogens spread via aerosol generation, cross-contamination, spattering, and risks associated with open flames, and are color coded for easy identification. For underground inoculation, it can penetrate the soil because it is rigid enough.

Inoculating Loops and Needles Operating Procedure

- By twisting the wire through the heat source until the entire length of the wire starts to shine red/orange from the heat, you can sterilize the wire inoculating loop.

- Before choosing the bacterium sample to be moved, cool the loop or needle.

- After use, the loop or needle is steamed up to sanitize it.

- To get rid of any germs that made it through the heating procedure, disinfect a 12-inch-diameter band around the heating device.

Applications of Inoculating Loops and Needles

- In order to study bacteria and fungus on semi-solid substrates, inoculating needles are employed in microbiology.

- Techniques for culturing organisms with needles are also employed in immunology, cell biology, and nanotechnology.

- For plate streaking, fishtail inoculating slant cultures, and inoculating stab cultures, the inoculation loop/needle is employed.

- Cell movement, microbial oxygen needs using thioglycolate cultures, and the gelatinization of bacteria are all studied using stab cultures. The inoculation syringe is particularly necessary for stabbing cultures.

- For inoculation, periodic dilution, safe sampling, transfer, and disseminating microbiological samples, inoculating loops and needles are used.

Advantages of Inoculating Loops and Needles

- The use of platinum wire in inoculating loops and needles allows for their quick heating and chilling, which reduces waiting time and boosts productivity.

- Nickel-chrome circles have the same resilience and quick cooling after heat sterilization.

- Because disposable inoculating loops and needles don't need to be flamed, there is no danger of contamination from pathogenic microbes forming an aerosol.

Limitations of Inoculating Loops and Needles

- Platinum cables are more expensive. The cost of disposable plastic rings and needles is also high.

- It takes time to inoculate, and if errors are made, the samples' purity may be compromised.

- Working with numerous data increases the risk of contamination and human mistake.

Precautions

- After the heating process is finished, the area near the heating device needs to be cleaned in order to get rid of any germs that persisted after flaming.

- After flaming, the hot loop or needle shouldn't be handled with the hand; instead, it should cool for a while before being used. The transferable sample microbes are killed by hot loops and needles.

- Before and after use, the wire coils and needles should be flamed.

- To avoid gouging the agar dish, streaking should be done carefully with swift, fluid motions.

Inoculating Loops and Needles Examples

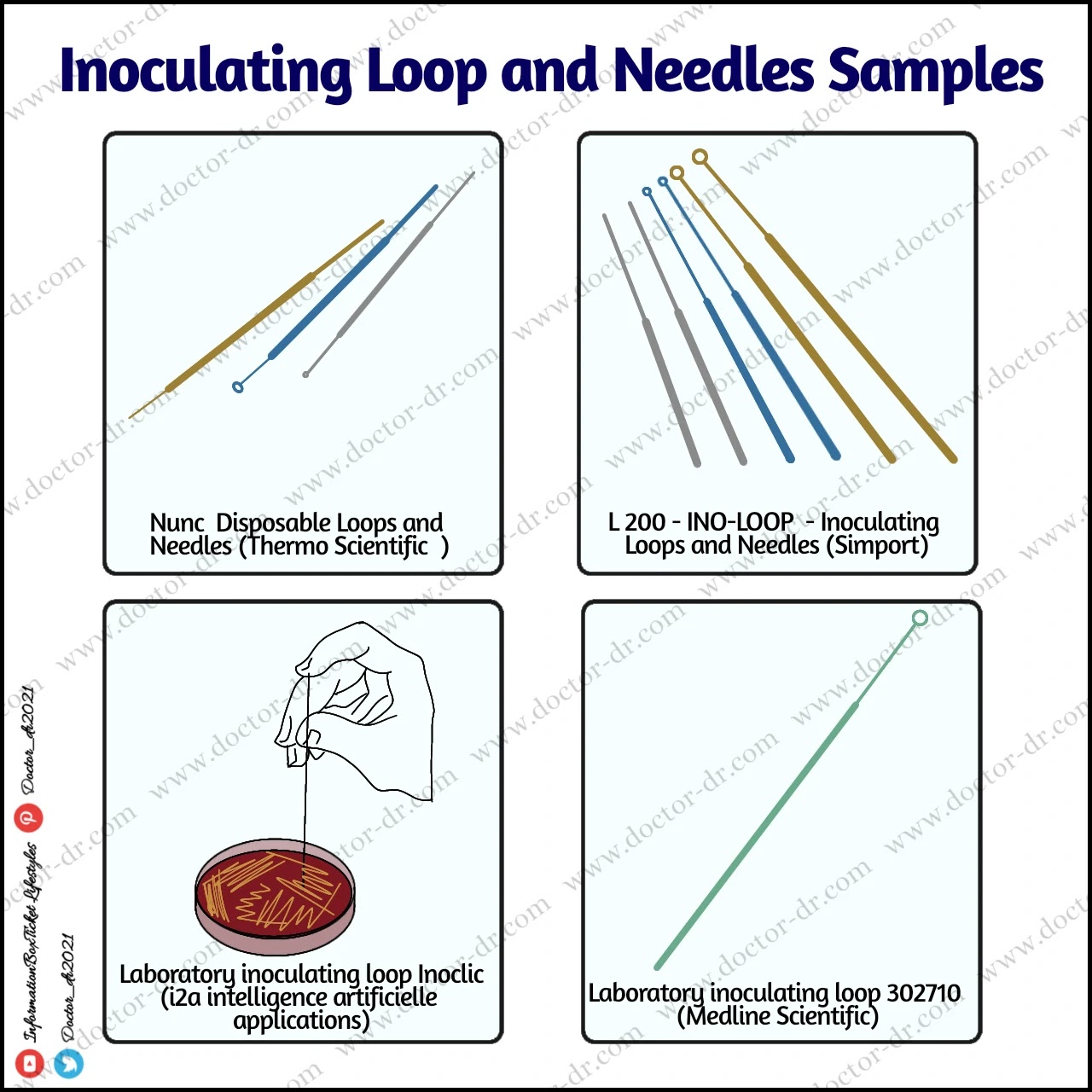

Laboratory inoculating loop Nunc™ (Thermo Scientific)

- Thermo Scientific's nunc loops and needles are thrown away after use.

- They are made of styrofoam, which is non-toxic.

- Accidental releases are prevented by the properties of the liquid adhesion.

- These precisely molded products can be used in a variety of industries, such as biotechnology, medicines, research laboratories, and the production of vaccines and testing tools

Laboratory inoculating loop L200 Ino-Loop™ (Simport Scientific)

- Loops and needles that are pliable and smooth permit consistent streaking without damaging the gel's surface.

- enclosed in safe, tamper-evident zip-lock resealable containers that have undergone sterilization.

- Inadequate sterilization-related cross-contamination is eliminated.

Laboratory inoculating loop Inoclic (i2a (intelligence artificielle applications) S.A.)

- When inoculating agar or tubed maintenance media or suspending bacteria in a liquid medium, INOCLIC is recommended.

- By combining mass spectrometry and AST on agar media, INOCLIC can initiate identification using the same agar dish.

Laboratory inoculating loop 302715 (Medline Scientific)

- They safeguard the gel surface by providing consistent and clear streaking while being smooth and flexible.

- They arrive in convenient batch and expiry date-marked clean peel pouch packets.

.webp)