The discipline of bioengineering combines natural sciences and industrial sciences to enhance goods and services by utilising organisms, cells, and molecular analogues. To create the intended product, biological processes are combined with chemical engineering concepts.

It also refers to the application of technological knowledge and scientific concepts to the creation and implementation of materials, buildings, tools, devices, systems, and processes in order to accomplish a specific goal.

Oxidating aerobic fermentation processes adequately remains a problem in biochemical engineering. The oxygen transfer capability of traditional bioreactors is far exceeded by the oxygen needs of high-density cultures.

Table of Contents

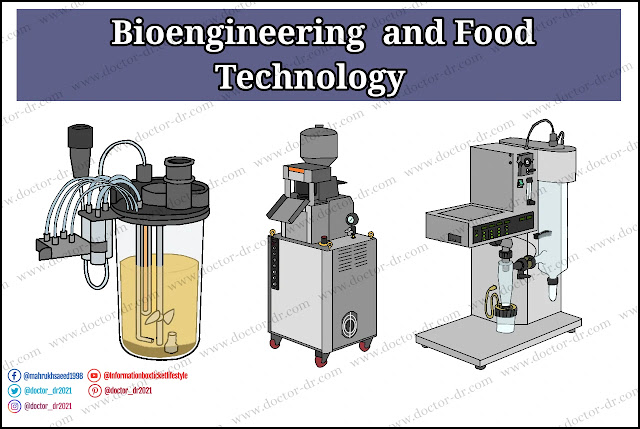

Bioengineering and Bioreactor

- A bioreactor is a vessel specially built for growing microorganisms at high densities and giving optimal development circumstances.

- A bioreactor is typically a circular receptacle with hemispherical top and bottom that is made of stainless steel or glass and ranges in size from a few litres to a few cubic metres.

- The bioreactor's capacity can differ. Bioreactors include the microbial cell (few mm3), shake beaker (100-1000 cc), laboratory fermenter (1 - 50 L), pilot scale (0.3 - 10m3), and plant scale (2 - 500 m3).

- Alcoholic drinks, for example, require basic fermenters and do not require aseptic conditions.

- High-value and low-volume goods necessitate a more complex operating system and aseptic circumstances.

- Bioengineering aids in the development of the optimum fermentation system for each microorganism based on its process requirements.

- Bioengineering designs and builds stainless steel fermenters with sizes varying from 30 to 50,000 litres for microbial growth. (bacteria, archaea, yeast, and extremophiles).

- Reaction rates are commonly stated as the amount of reactant consumed or the amount of product produced per unit of time.

- Thus, the numbers are moles per litre per unit time, denoted by M/s, M/min, or M/h.

Calculating the Reaction Rate of Sucrose to Ethanol and Carbon Dioxide Fermentation:

Rate=Δ [B]/Δt = −Δ [A]/Δt

C12H22O11 (aq) sucrose + H2O (l) → 4C2H5OH (aq) + 4CO2 (g)

According to the factors in the balanced chemical equation, the reaction rate of ethanol formation is four times quicker than the reaction rate of sucrose consumption:

Δ [C2H5OH]/Δt = −4Δ [sucrose]/Δt

- Because the concentration of the reactant, sucrose in this instance, declines with time, the number of [sucrose] is negative.

- As a result, in the Equation, a negative sign is placed in front of [sucrose], and the rate of change of sucrose concentration is represented as a positive number.

- In contrast, because ethanol concentration rises over time, the rate of change is naturally represented as a positive number.

- In the balanced chemical equation, the reaction rate is frequently stated in terms of the reactant or product with the lowest coefficient.

Because sucrose has the lowest coefficient in the sucrose fermentation reaction, the reaction rate is usually described as follows:

Rate=−Δ [sucrose]/Δt =1/4(Δ [C2H5OH]/Δt)

Equilibrium

Chemical processes that can occur in both directions are denoted by double lines in formulas.

The reaction is said to be at equilibrium when the pace of the reaction is the same in both ways.

1. Effects on Temperature

- When the temperature rises, molecules have more kinetic energy, which increases collisions and the quantity of activation energy, causing the process to progress faster.

- Because chemical processes are involved, higher temps accelerate fermentation.

2. Effects on equilibrium.

- Enzymes are proteins that function as catalysts; in wine, polyphenol oxidases such as lactase and tyrosinase are examples of enzymes that induce browning in liquid.

- Winemakers add enzymes to juice to break down pectin in the juice and enable settling and clarifying.

- Lactase is an enzyme that breaks down the milk sugar lactose; individuals who lack it have lactose sensitivity.

- Tartaric acid dissociates (loses protons) in water. Temperature Influences Fermentation The lower the temperature, the slower the rate of fermentation (in whites, the optimal rate is about 1°B per day, reds 3-4 °B at peak fermentation).

- When it gets too cold, the pace drops almost to a halt.

- If the temperature rises above 95°F (100°F), the yeast will die and the fermentation will stall. (stop).

3. Effect of oxygen

- Microorganisms require air from the fermentor, which supplies it. The dissolved oxygen concentration should not decrease below the crucial dissolved oxygen concentration during fermentation.

- As a result, the fermentor's oxygen-transfer rate fits the culture's oxygen uptake rate while keeping dissolved cellular concentration.

- Fermentors have a practical maximum KL, which is decided by fermentation operating circumstances, in order to balance supply and demand. This can be accomplished by:

- Controlling biomass concentration.

- Controlling the specific oxygen uptake rate.

- A combination of (1) and (2).

- Glucose levels decide cell growth extents and mass, while oxygen dissolved and DO levels impact growth rates. The oxygen transfer through the liquid layer encircling the gas bubbles limits the transmission of oxygen from gas bubbles to cells.

NO2= kLa (C∗ −CL)

Where NO2 is the oxygen transfer rate (OTR) with the units of mgO2·l−1h−1 and;

- kL: O2 transfer coefficient (cm·h−1)

- a: gas-liquid interface area (cm2·cm−3)

- kLa: volumetric O2 transfer coefficient (h−1)

- C∗: saturated dissolved oxygen (mg·l−1)

- CL: actual dissolved oxygen (mg·l−1)

4. Influences on Fermentation.

- Fermentation also produces heat as a byproduct; if no heat is lost the temp rises 2.3 °F for each drop of 1°B.

- As a result, cooling covers are installed on containers.

- For every 10°F increase in temperature, yeast development will double.

- Yeast and bacteria (including rotting microorganisms) thrive at pH levels around 5.5.

- Keep must at 2.9 to 3.6 pH to avoid deterioration. Lower pH levels cause yeast to develop more slowly.

- SO2 inhibits the development of all microbes and destroys some of them.

- Add 30 to 50 PPM to the must to deter non-wine yeasts and lactobacillus.

5. Heat Transfer in Fermentation

- There are two kinds of common heat transfer uses in bioreactor functioning.

- Batch sterilisation of watery material in situ. The fermenter receptacle holding the medium is heated with steam and kept at sterilisation temperature for a period of time before cooling water is used to return the temperature to normal working conditions.

- Temperature management while the reactor is running. Heat is produced by the metabolic action of organisms.

- Some microbes require high temperatures (e.g., psychrophilic and thermophilic microorganisms). Heat transmission designs for bioreactors include a jacketed vessel, an external coil, an internal helical coil, an internal baffle-type coil, and an external heat exchanger.

- The external jacket and filament provide a small heat transmission region. As a result, they are rarely used on a large basis.

- Internal coils are commonly used in production containers because they can be run at liquid velocity and provide a reasonably large heat transmission area.

- However, the coil conflicts with vessel mixing and makes cleaning the reactor challenging.

- Another issue is cell layer formation on the heat transmission surface.

- The external heat exchanger device is independent of the reactor, simple to expand, and has the greatest heat transfer capacity.

- However, sterility requirements must be met, the cells must be able to resist the shear forces applied during pumping and aerobic fermentation, and the residence time in the heat exchanger must be short enough to prevent the medium from becoming oxygen-depleted.

- Double-pipe heat exchanger.

- Shell and tube heat exchanger

- Plate heat exchanger

- Spiral heat exchanger

The temperature differential in bioprocess is comparatively small. As a result, plate heat exchangers are infrequently used.

6. Mass transfer in Fermentation

- In mixtures with local concentration change, mass transfer happens.

- When a dye is poured into a cup of water, for example, mass-transfer mechanisms are responsible for the movement of dye molecules through the water until equilibrium is reached and the concentration is consistent.

- Mass is moved from one location to another in the system due to a percentage differential or gradient.

- Because many bioprocessing systems are aerobic, gas-liquid mass movement is critical. Before it can be used, oxygen must first be transferred from the gas mass to the cell surfaces via a sequence of processes.

- The absorption of oxygen in soup is extremely low. As a result, improving gas-liquid mass transfer during oxygen cultures and fermentations is always a top goal.

Applications of Bioengineering

- varying bacteria have varying process needs; bioengineering creates the best fermentation system for each microbe.

- Bioengineering creates bespoke stainless steel fermenters with sizes ranging from 30 to 50,000 litres for microbial cultivation (bacteria, archaea, yeast, and extremophiles).

- Supply of oxygen, agitator dimensioning, heating and refrigeration circuit. These are important considerations when confronting microbe populations. A high material transition coefficient (kLa number) is frequently required with a high power supply. Expert expertise and CFD models are available from Bioengineering.

- Bioengineering has over 40 years of expertise developing aeration methods to ensure optimum oxygen delivery for your microorganism and process.

- You name the problem; Bioengineering will solve it. Anaerobic or with high oxygen demand, high foam development, bio-safety standards, high metabolic heat, constant fermentation, GMP production, high cell density - you name it, Bioengineering will solve it.

- Corrective agent dosage vessels, such as acids, bases, and anti-foams, are normal system features that are completely incorporated into the fermentation system.

- We prioritise short heating and cooling times to prevent detrimental impacts on culture media and process duration.

~1.webp)

.webp)

.webp)